DFM Experts: Personalized 1-on-1 Tutoring & Services

We are a team of tutors and freelancers that are hireable on an as-needed basis for professional help with your projects.

Optimize your product with our Design For Manufacturing expertise. Get 1-on-1 customized tutoring or professional services. Free 15-minute consultation!

3 Types of Service

Tutoring

Customized 1-on-1 tutoring sessions. Don't waste time & money in class. Learn only what you need for your specific projects, and nothing more!

Collaborative

Share screens with us to cut costs and learn along the way. More communication increases our understanding of your project.

Contract

Hourly rate or fixed price for agreed upon deliverables and deadlines.

Our Design For Manufacturing Tutors & Freelancers

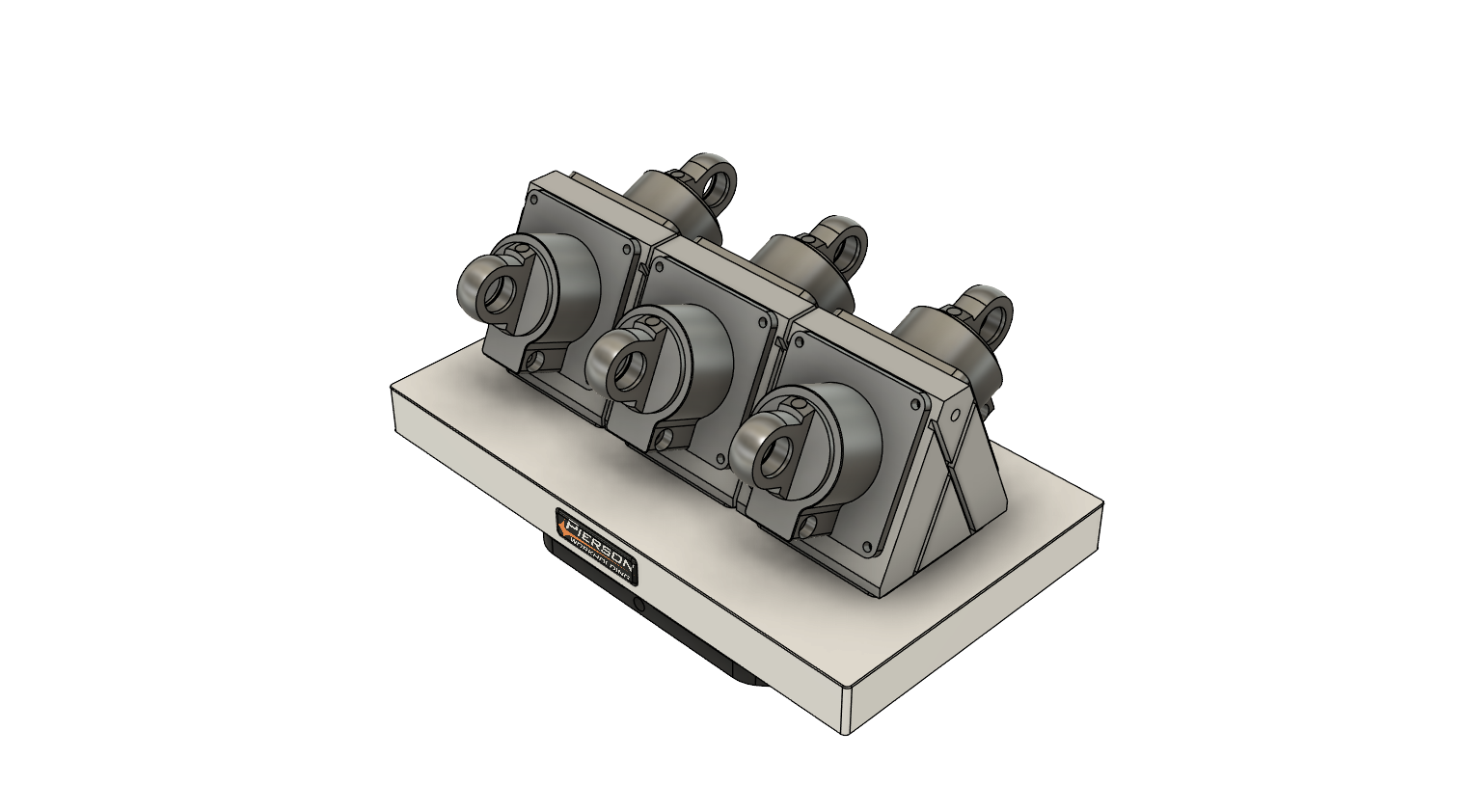

Design For Manufacturing Gallery

0 Reviews for Tutors & Services

Design For Manufacturing Services We Provide

Cost Estimation

Cost Estimation provides accurate and detailed cost analysis tailored to the manufacturing design, helping clients to effectively budget, compare material and production process options, and optimize resources while ensuring project feasibility and profitability.

Prototyping and Testing

Prototyping and Testing under the Design For Manufacturing (DFM) umbrella involves creating preliminary versions of a product to evaluate and validate its design, functionality, and manufacturability. This sub-service includes 3D modeling, producing physical prototypes using various techniques such as CNC machining or 3D printing, and performing rigorous testing to identify and resolve potential issues early in the development process. The goal is to refine the product design to ensure it meets all specifications, requirements, and is optimized for cost

Assembly Process Design

Assembly Process Design focuses on creating efficient, cost-effective, and scalable assembly procedures. This involves analyzing product designs to optimize for manufacturability, selecting appropriate tools and methods, and streamlining workflows to ensure consistent quality and reduced production times.

Production Workflow Optimization

Production Workflow Optimization focuses on analyzing and refining manufacturing processes to enhance efficiency, reduce waste, and improve overall production quality. This sub-service leverages advanced techniques and tools to streamline operations, ensuring seamless integration from design to final production, thereby accelerating time-to-market and optimizing resource utilization.

Tolerance Analysis

Tolerance Analysis ensures that parts and assemblies fit together seamlessly by systematically assessing the allowable variation in dimensions and material properties. This process minimizes manufacturing defects, enhances product functionality, and reduces production costs, all while maintaining design intent and quality.

Material Selection and Analysis

Material Selection and Analysis involves evaluating and identifying the most suitable materials for a product's design and manufacturing process. This includes considering factors such as material properties, cost, availability, environmental impact, and compatibility with manufacturing techniques to ensure optimal performance, durability, and efficiency in production.

Not sure what you need?

Contact us, and we can point you in the right direction.

About Our Tutors

ON-DEMAND PROFESSIONALS

We are a team of tutors and freelances that are hire-able on an as-needed basis for professional help with your projects. Call us with a quick question, or a big project. Our availability is flexible. We have a variety of skillsets and prices.

SCREEN-SHARE TUTORS AND FREELANCER

We teach remotely, so you can learn from the comfort of your home, from the jobsite, or from the beach! We teach classes via Zoom screen-share, so we can see each others' screens and cursors. It can take hours to search online for 1 simple piece of information, but just minutes to ask your private tutor. Don't struggle alone, get help from a real person online!

Remote & On-Demand Help

Design For Manufacturing Tutors and Services

Get on demand Design For Manufacturing classes! We are a team of tutors and freelancers that are hire-able on an as-needed basis for professional help with your projects. Call us with a quick question, or a big project. Our availability is flexible. We teach remotely, so you can learn from the comfort of your home, from the jobsite, or from the beach! We teach classes via Zoom screenshare, so we can see each others' screens and cursors. It can take hours to search online for 1 simple piece of information, but just minutes to ask your private tutor.

Advantages of Online Tutors and Services

Effective

The process of learning 1-on-1 with a live tutor lets you actively participate in the learning. You can immediately repeat a concept in your own words, ask clarifying questions, or demonstrate a concept back to your tutor to ensure understanding.

Efficient

Save time and resources by learning from the comfort of your home. Avoid commuting expenses and focus on learning only the tools you need with personalized lessons tailored to your specific workflow.

Recordable

No need to take notes! We record your lessons so you can replay them at your own pace later. Keep these recordings for future reference and reinforce your learning whenever needed.

Fun

Learning with a dedicated tutor makes the experience enjoyable and interactive. Discuss problems, practice together, and enjoy the human conversational element that brings life to online learning. Reach out anytime you need assistance!

Tutors & Services Philosophy

Don't Learn Alone

Professionals these days are sitting alone and staring at their computers. They spend years searching online for tools that will increase their workplace efficiency. They hunt through forums and watch lengthy videos, trying to find the right pieces of information.

Sometimes they just have one small question that would take a person two minutes to answer, but customer support lines are a thing of the past. Big companies will direct you to an FAQ that will hardly begin to answer your question.

Bring Back the Human Connection

We strive to bring human connection back to the work environment. Our tutors work directly with you to solve your problems, similar to the way an apprentice works hand-in-hand with a skilled professional.

Screen-share technologies like Zoom have allowed us to work together in real time. We can see each others' screens and cursors. We can switch from one screen to another to easily share information. We can even turn on our webcam for a more human interaction.

Tutors, Services, or Both

Sometimes our clients want to learn a program from beginning to end; sometimes they completely hand over the services to us; and other times, they want something in between.

Some clients want to be able to use the program on a basic level and let us do the hard stuff. Others want to co-work with us, supervising our work to ensure their artistic vision is realized. Along the way, they may learn some tools of the trade.

By the end of the process, some clients are able to wean themselves completely off of our services and are empowered to do the work themselves. If they get stuck or behind on a deadline, they use us as a lifeline. They can call anytime—even if it’s just a 10-minute question—we are here to help.

Design For Manufacturing FAQs

How can Design for Manufacturing (DFM) improve product quality?

Design for Manufacturing (DFM) can improve product quality by simplifying the design to minimize manufacturing complexities, ensuring consistent and efficient production processes, reducing the likelihood of defects, and facilitating easier assembly and inspection.

How can Design for Manufacturing (DFM) shorten the product development cycle?

Design for Manufacturing (DFM) shortens the product development cycle by identifying and addressing manufacturing issues early in the design phase, reducing the need for costly revisions, improving communication between design and manufacturing teams, and enabling faster transition from prototype to production.

What are the common challenges faced when implementing Design for Manufacturing (DFM) in a project?

Common challenges in implementing Design for Manufacturing (DFM) include communication gaps between design and manufacturing teams, balancing cost with functionality, limited understanding of manufacturing processes by designers, resistance to change in established workflows, and the need for early collaboration and iterative prototyping.

How can Design for Manufacturing (DFM) reduce production costs?

Design for Manufacturing (DFM) can reduce production costs by simplifying product designs, standardizing components, improving manufacturability, minimizing material waste, reducing assembly time, and enhancing process efficiency, ultimately leading to fewer production errors and lower labor and material expenses.

What are the basic principles of Design for Manufacturing (DFM)?

Design for Manufacturing (DFM) involves the following basic principles: simplifying the design, standardizing components and materials, designing for ease of fabrication and assembly, minimizing the number of parts, using modular design techniques, designing for efficient material use, and considering the capabilities of manufacturing processes and equipment.

What are the key considerations when designing a product for manufacturability?

Key considerations for designing a product for manufacturability include: 1. Simplifying the design to reduce part count and complexity. 2. Selecting materials that are readily available and easy to work with. 3. Ensuring ease of assembly by designing parts that fit together without excessive force or alignment. 4. Considering the capabilities and limitations of the manufacturing process and equipment. 5. Minimizing intricate and delicate features that could increase the risk of defects. 6. Allowing for efficient testing and inspection procedures.

How does Design For Manufacturing (DFM) impact the choice of materials in a project?

Design For Manufacturing (DFM) impacts the choice of materials by prioritizing those that are easier to process, cost-effective, and compatible with the chosen manufacturing methods, thereby ensuring efficiency and reducing production costs while maintaining product quality.

How can Design For Manufacturing (DFM) assist in minimizing waste during production?

DFM helps minimize waste by optimizing product design for efficient manufacturing processes, reducing material use, and improving assembly procedures to decrease errors and defects.

How does Design for Manufacturing (DFM) facilitate easier assembly of products?

Design for Manufacturing (DFM) facilitates easier assembly of products by simplifying designs, reducing the number of parts, standardizing components, and ensuring ease of fabrication, which minimizes errors and streamlines the assembly process.

How does Design for Manufacturing (DFM) influence product reliability?

Design for Manufacturing (DFM) influences product reliability by ensuring that products are designed with ease of manufacturability in mind, reducing the likelihood of manufacturing errors, material defects, and assembly issues, ultimately resulting in more consistent, high-quality products that are less prone to failure.

We Specialize in Design For Manufacturing and Beyond

More Services We Provide

More Software we Teach